Goffys '59 A10

Goffys '59 A10

Goffys '59 A10

Goffys '59 A10

Not Tonight Josephine...!

Originally written 2002, this has been updated Feb. 2004 with additions in italics.

Updated again 2007-2008

Also 2009-10, Feb 2016 & Aug.2020

I bought this A10 from a chap called Paul Philips in Chalfont St. Giles in 1977. She was dismantled then but in fairly large bits, so I reassembled her with a respray in something like Golden Flash beige. All the tinware was there so it went back more or less original. The speedo was missing as was the carb., so I fitted a concentric that I had laying around and as it ran so well it was eventually replaced with another, although larger 30 mm version. The crank was on standard grind and thebores were also standard so it must have been a fairly lowmileage bike and so promised a few trouble free miles. Iíd just sold my plunger A10 that had been pulling a sidecar for some time, so with the help of some scrounged fittings she became a combo.

Common knowledge has it that cheap cars killed off outfits in the early 1960s but by the mid 70s cars were still too expensive for many impoverished youngsters so cheap old British bikes were the way to go with a second pulling a chair to carry the washing, shopping and broken-down or non-running bikes. I had a Dommie Cafť racer with a single seat so something to carry the girlfriend as well was needed. One of my friends had an Ariel outfit, another an A10 and another made a living as a window cleaner around Marlow with a double adult sidecar on an M21.

I ran Josephine far about 3 years as an outfit and did thousands of miles all over the country on club runs with the Bracknell Lepers carrying all the camping gear, spare petrol and tools. She was very reliable and I can only remember 1 breakdown, in Salisbury when the clutch fell off the end of the mainshaft - which was my fault for not putting it on properly in the first place, without a tab washer.

After the first winter I had to have a rebore done, as she was becoming very oily and smoky. I was disappointed to have to have it taken out to +0.30 as it wouldnít clear on any less. I had no idea of the mileage, as there was still no working speedo, but one winter didnít seem enough to wear out a top end. A clue was a persistent freezing carburettor whenever it was cold and wet; eventually I discovered that the rear wheel was throwing water and muck through a hole in the mudguard, past where the battery would have originally been (now in the sidecar) and straight into the bellmouth on the carb.! A filter was fitted and I have so equipped every other bike Iíve owned. Fork bushes and wheel bearings were frequently needed so I had a spare set of forks and a rear wheel that I would rebuild ready for when they would be needed. Every fortnight or so I would have to reset all the sidecar mounts and chains and sprockets didnít last too long either. If I had ridden around gently all this heavy maintenance wouldnít have been necessary, but I was often having to keep up with solos so she given a bit of stick.

I was getting tired of being cold and wet in the winter so a Reliant van was bought. Just like Del Boys but red, so off came the sidecar and despite having had to weld a cracked downtube below the headstock where a fitting had come loose in the past she still handled perfectly. By this time I had a Commando as well so Josephine was relegated to being a working hack and winter bike.

After the clutch fell off I fitted a Plunger A10 clutch which as well as being much stronger had a duplex chain, which made maintenance much less frequent. Always valuable on an outfit as the clutch is on the same side as the chair (for those brought up on Jap bikes and still reading), or in my case wooden box. This has the unfortunate effect of lowering the gearing from standard and alternative sized engine sprockets were not available for plunger A10s. I tried a larger gearbox sprocket but as the gearbox was running slower the change suffered.

That was eventually changed for a Norton clutch which although only having a single row chain had an extra cush drive and allowed for the easy changing of gear ratios. It is now on 22 teeth on the engine; that is 1 tooth more than std. and with the Norton clutch being 1 tooth less raises the gearing substantially. This obviously slows the acceleration some but with the benefit of the fairing allows comfortable cruising at 75-80 mph. The Norton clutch is bullet proof and I haven't needed to look at it since it went on. Still perfect Mar. 2008

The Dustbin fairing I picked up at Kempton Park autojumble for £20 and, although it had no fittings, was in good condition apart from a hole in the front about big boot size. Iíve mounted it using bonded rubber mountings, which isolates it from the engine vibration so it isnít at all noisy. The down side is that the mounts allow flexing that has caused the gel coat to crack. Really gusty side winds can be interesting but generally it is a great improvement on when the bike was unfaired. Prejudice against fairings I canít understand. Fit a well-designed fairing and the bike will be faster, use less petrol, and you will stay warmer and dryer. Also every post 1950s racing bike Iíve seen has a fairing so they cannot be accused of having no macho appeal. It makes the bike much bigger so takes up more space in the garage and the lock has had to be reduced so manouevering is more difficult. But the advantages outweigh the disadvantages, particularly staying dry.

I run a cartridge oil filter in the return line and use 20/50 and it is still on std. big ends having had 1 grind to 10 thou on the bush. The last bottom end rebuild was 1996 when I fitted new shells and had a new bush milled to suit the crank. That was 30,000 miles ago (Iíve got a speedo now!) and all is well for a couple of more years at least. That was the second bottom end rebuild, the first was so long ago I can't remember when, but I do remember that the total engine rebuild cost £80.00. You canít even get the pistons for that now. First big end grind Jan. 2010

I thought the ends were going in June 1998, but that turned out to be worn splines on the crank, which make an annoying noise but wonít affect the reliability.

An annoying rattle, especially when cold was a small end wearing out, which was replaced in 1997, and apart from the usual servicing no other engine work has been needed. At the same time as the small end I fitted an alloy head from a Road Rocket and opened the port out to 30 MMNov. 1998 I started using Premium unleaded mainly to save money and also to find out if the prophets of doom were right after all about valve seat recession. All was fine for 3 months or so when I was using the bike mainly for daily trips to work and other short journeys. April 1999 I went to a rally in Portsmouth (about 80 motorway miles away) and as usual I was late setting off so the journey down was at 70-80 MPH.We had a good fast ride to Poole & back, (particularly on the way back as we got lost and managed to turn a 20 mile journey into 50) with some more modern machinery. The trip home was done at speed also as this was the day of the second K-Tec failure and by the time it was half way home it was getting dark and p-----g down with rain. Around Guildford, the engine started popping and banging in the exhaust, the exhaust pipes had turned blue and there was very little compression on either side. These are the classic symptoms of the valve clearences closing up due to valve seat recession... After resetting the tappets when I got home I started using Redline Lead substitute.

After a couple of years of this the compression gradually disappeared again, and on dismantling I was surprised to find the valve seats OK but the valves had burnt out. I had SRM fit bigger inlet valves, gas flow the head and hardened exhaust seats just in case. With hindsight I probably had either poor quality pattern exhaust valves or more likely inlet valves incorrectly fitted on the exhaust side & I probably wasted my money having the exhaust seats done.

The gearbox has had one major rebuild using a replacement cluster from a C12 which is identical but unlikely to be worn out given the low power and one minor. Same again in 2008, most of the cluster coming from a C 12 box from a jumble with the existing main shaft. Pattern layshaft sleeve gear bushes that were the wrong length & diameter were annoying.

The rest of the bike new Koni shocks, taper roller headraces and thatís about it. Several sets of fork bushes have been recently bought but none have proved to be accurately enough machined. I've a mixture of 2 sets fitted now with the outsides of the upper bushes tinned with plumbers solder to give a good fit in the sliders. A new set of stanchions were also bought at an autojumble but were promptly binned for the same reason. Good stancions/bushes available on my site Jan. 2010

Konis still good 2008, quality product.

However, the electrics are another story. As standard she ran 6V lights faultlessly for years (only one dynamo rebuild being needed) - the problems started when I first tried to convert her to 12V using a JG conversions unit in the late 1980s. This never kept the battery fully charged and burnt out the dynamo trying so I retreated to 6V for several more years. However brighter car headlights and ever-dimmer eyesight forced me to try again. The first K-Tek unit lasted a couple of months and then failed open circuit. The next didnít last as long but failed in full charge mode, blowing all the bulbs 80 miles from home...hence the title of this article. I eventually fitted a unit from Al Osborne and a bloody great battery in the pannier and all is well. Also recently fitted has been a toothed belt drive to the dynamo which has the added benefit of speeding it up, so with the raised overall gearing the dynamo revs at any given speed are probably about the same as standard. The dynamo belts last only 2000 miles or so, which is a bit of a pain. The V Reg II is still OK 2008

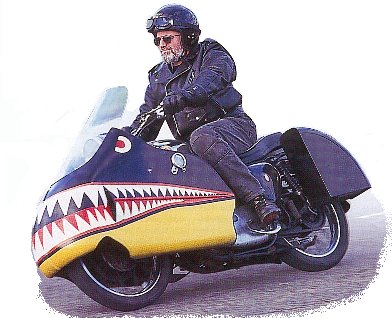

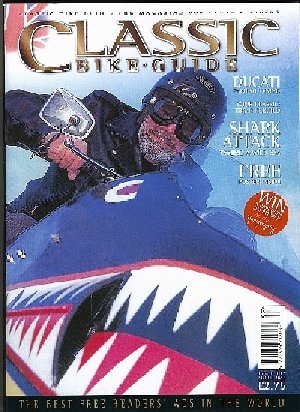

Josephine was featured on the cover of the March 2000 edition of Classic Bike Guide and given a glowing write up by staff writer Steve Wilson - I think he was particularly impressed/amused by the shark's tooth design copied from a photo of an American WW11 Curtiss P40 fighter plane. Pictures of it have been seen in Back Street Heroes and other sundry rally features but this was the only time it's had a full article written about it.

Josephine is the most reliable bike any one could ask for. She starts first or second kick, doesnít use much oil, does 60 mpg, handles well, stops OK (Triumph 2LS front brake) comfortable on a long run and keeps me warm and dry. What more could one ask for?

Age is beginning to take its toll on Josephene as much as me, and apart from special events stays in the garage. I've got a new cluster for the gearbox, which is all it really needs. I think I'll go back to a 28MM carb as although she's got plenty of power at higher revs she's a bit flat lower down. This combined with lowering the gearing will make it more suitable for squrting around the lanes near where I live.

Oct 2004 Now pressed into use as a winter bike once more. Covered in grease, she's loving it.

Same again Oct. 2005

I used to use Josephine to commute 25 miles a day most days during the summers until 2002, and it was still a practical proposition to use an old bike. A large proportion of Britains workforce went to work on bikes in the 1950/60s and they made it most days. If you build these old things carefully they can be reliable and repay you with lots of fun.

I work from home now, so keeping Josephene in tip top condition isn't as important

Apr.2006 This winters use has seen the poor old girl becoming rather sad. The cycle parts need looking at and the performance has seriously deteriorated. She's in the back of the garage again but it's her 50th birthday soon so she will have to be revived for that.

Nov. 2007 Rebuild has finally started. I've replaced the s/arm as the rubber bushes had 'gone soft' making the handling lousy. New shoes in the rear brake. Bushes & stanchions replaced in the front. I've found some good ones, they cost but are worth it. Wheel bearings & head race bearings were replaced last time so are OK. New tyres, I'm trying the new Avon Roadriders which are narrower than the AM20/21 they replaced so it'll be interesting to see how it handles. Koni shocks still OK. These are very old now but still spot on.

The gearbox was whining in 2nd & 3rd so I've replaced the cluster with another from a C12 again, new bushes & bearings

The barrels were replaced with a good used std. set before & they are still OK with little wear. Compression was low & there's blowby past the rings but the pistons are OK so a new set of rings is all that's needed.

The guides are worn a little more that I would like, but it didn't rattle or smoke before I took it down so they are staying with only a lapping in of the seats.

The original 356 camshft from 1959 is still almost like new. The followers are slightly scuffed but as they started life in another engine it's hardly surprising and will be OK.

The big ends are amazingly still fine, on std. from new. There was a little play on the bush but nothing that would cause any problems. The main bearing journal was 1/2 a thou. out of round last time so it probably needs grinding this time. The drive side main has some up/down play so will be replaced.

As mentioned before the splines on the crank were worn so although I could possibly get that repaired I have another crank, also on std, so I'll use that and have it balanced this time.

The bush I used last time was a bronze insert in a steel shell. I can't remember to well back that far but I think that was what was originally fitted as well, so that's what I'm using again. Most suppliers offer a solid bronze version. The last one had the bronze pegged to the shell, the new one didn't so I've pegged it. The last one had an internal oil groove the new one didn't so again I've added one. Also last time I added 4 more 5/32" holes to allow more oil to reach the crank which I've also done again.

Jan. 2008 I couldn't shift the sludge trap plugs so F.J.Paynes (just outside Oxford - recommended) removed them when it was in for the mainbearing journal to be ground. It wasn't worn but there was rust where it had been laying around the P.O.s house/shed, so I had them remove the minimum amount of material and mill the bush to suit ( 1.5 thou" clearance) with the c/case clamped to the mill table. I had this done at work on the last rebuild and it proved OK.

The crank & rods went to Basset Down for balancing & I was told that I had odd rods. Sure enough the batch nos. are different. Either this bike had new crank, rods, barrels & pistons before I got it (it was all on std. when I first stripped it so unlikely) or it left Small Heath with odd rods. I've ridden worse & better A10s for vibration so it's difficult to say. The man at Basset Down weighed my other pair & arrived at a pair that he could match so the job's done.

April. 2008 The drive side mainbearing bought from God knows where was wider than the original meaning no endfloat when the cases were together. In hindsight I should have changed that but chose to remove the bush, have a few thou. taken off and replaced. I managed to distort the bush in the process which meant buying another, fitting it & having it milled to size. Ho hum

I ordered a set of big end nuts & bolts from a well known trade supplier, was appalled at the quality & was told that was all that was available. I phoned a few other dealers and couldn't find any better. I then stumbled on an engineer in the marine engine industry who had had similar problems when rebuilding his A10, so had a batch made by an engineering company which supplies parts for F1 teams. Made to the original spec to tight tolerences from the correct spec material, with rolled threads. This is very important as a cut thread can create what's called a 'stress raiser' which may lead to failure. He only supplied plain, not self locking nuts so I ordered a set from SRM. They were junk & were sent back.

Barrels & pistons are fine but I bought a set of rings from a well known trade supplier that were rubbish. When fitted into the bore the ring gaps varied from 10 - 35 thou! I bought some AE Pistons versions from TMS in Nottingham that are fine.

The bottom end is together & fitted. The primary is fitted. The Norton clutch is in fine condition needing nothing replacing. I'm waiting for some St./St. barrel nuts before fitting the barrels. The magneto gasket was missing from the gasket set from SRM & they're sending another. The driveside meanbearing oil seal was also missing. The oil pump gasket was totally the wrong shape, so I'm not impressed with that expensive item.

May 2008

The final assembly is complete except for the exhaust system. A Rocket Goldstar 2 into one system from TJ Wassell which didn't fit. They got the difficult bit right where it fits into the head but it runs about 3 inches from the frame rail at the front to 1 inch at the back. The silencer is OK. I'm sending the set back & hope they can supply a better one.

I put the old exhaust back on (an Armours version that also didn't fit properly).

The new one when it arrived fitted better but still not quite right where it enters the head on the primary side, the finned collar can't sit flush with the head as the bend is too tight. It'll have to be good enough. Irritatingly a friend has recently bought a similar set from Armours which looks perfect.

I started it up today, it fired second kick. Yippee etc. It hasn't got a front mudguard yet.. I aerosol sprayed it and left it to dry and my wife cleverly managed to knock it off the workmate onto the concrete paving. What is it called when you murder your wife?

I've done 10 miles or so around the village, all within pushing distance from home, but no problems so far. A really notchy gearchange quickly bedded in and there's still a slight clunk from the cush drive area so my selection of the best worn out bits I could find wasn't good enough. There's a whine in third which is annoying as the gears I used looked almost perfect. The forks are really stiff.

Oil leaks from the sump plate and the chaincase. I didn't have any silicone sealer left when I put the chaincase on so used the traditional gasket & goo - and got the traditional leak.

I can't get an MOT from my local 'classic friendly' dealer for a week so I'll wait before I out some serious miles on her but so far so good.

The engine feels very different with its different/balanced crank. It feels smoother but as I haven't taken it to any speed yet it's hard to be sure.

June 2008

So much for the engine feeling smoother. It's fine up to 50MPH, really smooth, then it starts to vibrate, 55 it's vibrating badly & by 65 it's almost unrideable. I've done 400 miles now so am able to open it up a bit but by 70 MPH it's painful to ride. It was a lot better with the old onbalanced crank & odd rods.

July 2008

I've taken it apart again and had the crank/rods examined at Basset Down. He swears that everything is spot on the std. BSA balance factor of 58%. He's rebalanced it again to 65% which should make it rougher at lower speeds but smoother at higher speeds, we'll see.

I'm on holiday for a while & with general lack of enthusiasm for 'doing it all again' it won't be back together until the end of August or so. SRM have just announced a new hexagon nut for the drive end of the crankshaft. This is a nice piece as it was very difficult to lock the existing collar with a 'C' spanner . Well worth having.

August/Sept. 2008

All back together again & run in. Moving the balance factor form 58% to 65% was supposed to move the vibration down the rev range so that at lower speeds it would vibrate more and at higher speeds less. Well, it is just as smooth at lower speeds & the vibration doesn't start to be felt until at least 60 MPH. By 70 it's vibrating quite badly but seems to smooth out towards 85MPH. Strange stuff. I wish I'd left it alone, it was smoother before. Saying that though it's a different crank so I've no idea what it would have been like without having it balanced.

The gearbox whines a little in second & third which is a little disappointing but I've another spare cluster in the shed so I can change it if it ever get much worse.

The handling is great. All new front end & the new swinging arm have made the world of difference and these Avon Roadriders are the business. The steering is very precise and it stays on line brilliantly. I went to Brighton for the Rockers Reunion a couple of weeks ago so set off early & had a great ride down with little traffic.

It took 2 hrs pressing on. The best time I ever did on my old Commando was 1 hr. 20 minutes, in 1979. That was from Marlow which is about 15 minutes nearer & I think the extra time must be from all the extra roundabouts that have sprung up at almost every road junction, mind you they're good fun scraping the footrests round.

May 2009

New rings in the old pistons didn't work, there was a lack of compression fairly quickly and on dismantling I found a lot of 'blow-by' past the rings.

Years ago I tried a pair of 8.25:1 Italian GPM pistons in another set of barrels. These I couldn't stop from pinking. I retarded the ign. until it was desperately slow but still it pinked. I acquired another set of barrels & pistons from somewhere & used these. I still had the original set in the loft & using the logic that I had a cast iron head when I last used them & now had an ally. one so the pinking would go away I've fitted them & guess what?. It still pinks. These GPM pistons were quite a bit heavier than the Hepolites so it has made the vibration worse as well.

I've fitted foam grips which help. I tried bar end weights but that didn't mage any difference. They may be alright for the slight tingling that you get with multis but with the ceasless pounding I have they're no good. Hepolites are unobtainable and I've had American Wiseco pistons recommended but they're even heavier than the GPMs and higher compression.

I took it to the Isle of Wight British bike rally this summer & it kept up wth the Commando, Trident, & BMW of my friends riding around the island but it was no fun. It's got to come down again.

November 2009

|

I've been talking to a man named Steve McFarlane who seems to know a thing or two about A10s. He started SRM eng. before selling out in around 2002. He runs his own engineering shop where he does the end feed crank conversion and also an electric start conversion for A10s amongst other things. So I'm taking the bottom end to him with my old crank to have that balanced by a man he knows who also knows a thing or two about A10s, and rebuilt with end feed. I'll have to live with the GPMs. The big ends were slightly down on min. size so I'm giving them they're first regrind. He also is able to weld & remachine the splines on the crankshaft. |

|

| This is the timing side ball & needle roller main bearing, photo coutresy of the BSAOC tech forum |

I was troubled by wet sumping. After the last rebuild it would empty its tank into the sump over a week, it had never been this bad before, so I removed the sprung loaded ball valve in the crankcase to find it clogged up with sludge.

Steve McFarlane does a modification to the crankcase that leaves the ball seating against the back of the oil pump so giving easy access if wet sumping gives trouble in the future.

I'm fitting a Pazon Smartfire ign. to replace the magneto.

Hopefully I will be able to put it back together over the Xmas holidays.

March 2010

It's taken longer than planned mainly due to the lousy weather. It was more or less finished after Christmas but there was no rush because of the snow, ice, rain, wind & bloody freezing cold.

It's done now, & I braved the bloody freezing (literally) conditions & started it up last Saturday. Started first kick which is always a good sign.

It is good. I've only done about 10 miles as it was soooo cold but it is very smooth up to at least 70MPH. The horrendous vibration that has plagued me has gone. It's smoother than it's ever been despite having the heavy GPM pistons. So three cheers to Steve McFarlanes balancing man & Boo Hiss to Basset Down. It also sounds crisper and the mid range is better. I've still to do some fine tuning with the ign. timing but so far I'm pleased with the results.

It starts easily & the Ammeter balances in top with the lights on around 40 MPH which is surprising as I've still got the 60/55W headlamp + the Pazon.

I've put a Battery Status Monitor (LED indicator) into the nacelle to tell me what's going on charging wise & also as a reminder when the ign's on.

I plan on taking it to France for the Triton Rally near Le Mans this August, it should be nicely sorted by then.

July 2010

I've been told that France has ethanol already in all grades of petrol, so as this attacks the old formula Petseal, I bought some stripper to remove the coating I put in in 1979 & replace it with some new ethanol proof Petseal. Bit of luck I did as the old Petseal was starting to go soft. It was still rock hard the last time I looked but the modern petrol has started to have a go at it.

A good time to have the tank resprayed as well.

Sept 2010

France & back with no problems - it's finally sorted. Well, only one problem. When hot there was a persistant misfire. This turned out to be the bearings in the magneto body spinning in the body. When hot there was enough clearance to allow run-out of the magnet of the elec. ign. On a Boyer or even a Pazon surefire this would cause mo problems but I had fitted a Smartfire which has a heavy solid magnet almost as big as a cotton reel. The Smartfire had been to NZ & back for testing before I figured this one out.

June 2012

It's never been a quiet motor but has recently become horribly (& probably expensively) noisy, sounds like the head of a 2lb. hammer flying around inside the cases. A bit depressing as after forking out to have the end feed conversion I really thought that I'd never have to split the cases again.

I'll tell more when I've mustered the enthusiasm to take it all apart again.

Dec. 2012

I've bought another dismantled A10 for it's engine so I might just start again & leave the bottom end std. this time. Engine was totally Knackered so it's on the shelves.

Nov. 2013

Still no enthusiasm, but have built a Dommi in the meantime - it's not only laziness.

Sept. 2015

I took it all apart again as far as the cushdrive sleeve, which was such a tight fit on the re-welded crankshaft splines that I couldn't get it off, so I took it to our local Brit bike MOTer cum repairs man and asked him to take the sleeve off. He knew the story about the awful noise so also split the cases to have a look. He reckoned thats all it was, was too much endfloat so put in a shim & re-assembled it again with new big end shells..

It now felt too tight to me with no endfloat at all, so I took it apart again. I noticed some bright marks on the drive side bob weight, just like it had been dragging on something. Closer inspection revealed that they lined up with the ends of the bolts that hold the primary chaincase to the crankcase & these had shiny ends. So that was the cause of the noise, the bobweight hitting one then two of the bolts & being forced towards the timing side & bouncing back again. There was also a mark on the crank where the outer race of the main bearing was touching, so I removed a 10 thou. shim & replaced it with a 5. Back together & it's nice & free, all I've got to do now is build the rest of the engine again.

I had new valve & guides fitted to the head while it was apart.

Despite Steve McFarlanes mod. to the oil pump it still wet sumped, so I bought a reconned pump from Draganfly. We'll see if this fixes it.

Feb. 2016

It's back on the road & running sweetly. The cause of the knocking was the crank hitting the heads of the chaincase bolts. The ball & roller drive side main is supposed to take care of the crankshaft endfloat - there should be none - it's supposed to be fixed by the ball bearing. Well it may have been when first assembled, but something allowed the crank to move towards the primary side until it hit the crankcase bolts. Maybe the whole mainbearing assy. moved in the crankcase, though this seems unlikely. Anyway, I've put spring washers + the ordinary washers under the chaincase bolts & the 5 thou. shim has restricted the endfloat. There is endfloat, it's not being held by the roller bearing when all tightened up, but I can't see any problem running it like it is.

I've only done a few miles, but I'll wait till I've done a couple of hundred or so & add some comments.

The bloody rockerbox is leaking oil, but after all the trouble I had this time getting the pushrods where they're supposed to go it'll have to leak.

Mar. 2016 The Draganfly oil pump has cured the wet sumping. I was losing something like a pint a week into the crankcases, but now after standing 2 weeks I can't tell if any has drained at all. The return flow back into the tank seems greater as well, money well spent there.

June 2018 After a few hundred miles the noise from the bottom end started to reappear so I pushed it into the back of the garage & got on with other things. Having stripped it down again I could see that the crank was hitting the chaincase bolts & the endfloat had increased again. OK, I give up, & took the bottom end back to steve McFarlane who diagnosed a problem when he'd fitted the end feed conversion. Despite everything being done up nice & tight this was allowing the crankshaft pinion on the timing side to move outward creating endfloat. The 5 thou. shim I'd fitted wasn't thick enough & the crank was still hitting the chaincase bolts.

It seems to be finally fixed now. I've done a few hundred miles and all is good. Thank Christ for that - after six years on & off buggering about.

August 2020 Didn't do much during the lockdown as it didn't reall need anything, just built up the centrestand stops with weld so it doesn't go too far over centre.

I've now fitted a 23 tooth engine sproket instead of 22. I was worried that it would feel overgeared but it is about perfect, wish I'd done it before. A 5 speed box would be good for the back lanes, there's a big gap between 2nd & third, but it reduces the vibration at all speeds & makes riding at 70 reasonable.

P.R.Goff

49 Chequers LanePrestwood Bucks. HP16 9DR

Telephone: 01494 868218 or mail me here Goffy

![]()